Magnetic Damper -

Magnetorheological Damper

As

tires

become ever lower in profile and roads get ever worse, ride comfort is

knife with two blades if a car is to have the sharp responses we like.

Various active damping systems have promised an answer here, and none

has been more impressive than Delphi’s MagneRide, the

magnetorheological damper system used by Audi, Ferrari and few other

mayor manufacturers.

Current car

suspension systems show the result of a very long development. However, fundamentally, suspension systems remain very crude.

Steel springs support the body, with a variety of linkages used to maintain the wheels in a helpful

geometry during their movement. To prevent the springs simply oscillating once they have been deflected,

dampers ("shock absorbers")

are used to stop the spring continuing to bounce. The resistance to

motion that the wheel has is therefore very much dependent on the

spring rate, and the speed and stroke of damper movement.

As a result, there are frequent trade-offs required in the design

of the suspension. For example, soft springing and little damping can

gain excellent vibration isolation. However, such a system will

bottom-out frequently on real world bumps. On the other hand, good shock

reduction is achieved by a system with a relatively stiff,

highly-damped system. And on smooth roads, the stiffer the suspension

is, often the better the resulting handling - but such an approach is

unacceptable on cars that must negotiate bumpy roads.

While active suspensions - where the entire car's mass is

supported by hydraulic or pneumatic rams - were once seen as the

answer, the complexity, fail-safe requirements, power consumption and

weight of such systems has seen their development slowed to a crawl.

Magneto-rheological dampers are answer to compromise between drivability

and comfort. MR damper systems that can actively change in their

damping abilities - quick enough that dive and squat, roll and pitch

can be compensated for, in addition to being able to alter their

behavior to suit the road and driving style.

General Motors (in a partnership with

Delphi Corporation,

Delphi Automotive Systems - the branch of GM) has developed this

technology for automotive applications. It made its debut in both

Cadillac (Seville STS build date on or after 15/1/2002 with RPO F55) as

"MagneRide" (or "MR") and Chevrolet passenger vehicles (All Corvettes

made since 2003 with the F55 option code) as part of the driver

selectable "Magnetic Selective Ride Control (MSRC)" system) in model of

year 2003. Other manufacturers have paid for the use of it in their

own vehicles.

These types of systems are available from OEMs for several

vehicles, including the Acura MDX, Audi TT and R8, Buick Lucerne,

Cadillac CTS-V, DTS, XLR, SRX, STS, Chevrolet Corvette, Camaro ZL1,

Ferrari 458 Italia, Ferrari 599GTB, Ferrari F12 Berlinetta and Holden

HSV Commodore.

These systems were produced by the Delphi Corporation and now by

BWI Group and

LORD

under the proprietary name MagneRide. As of 2007, BMW manufactures cars

using their own proprietary version of this device, while Audi and

Ferrari offer the Delphi's MagneRide on various models. Porsche has

introduced magnetorheological engine mounts in the 2010 Porsche GT3 and

GT2. At high engine revolutions, the magnetorheological engine mounts

get stiffer to provide a more precise gearbox shifter feel by reducing

the relative motion between the power train and chassis/body.

As a continuously adaptive system, it adapts the damping

characteristic to the profile of the road and the driver's

gear-shifting habits within just a few milliseconds. Using magnetic

fields, magnetic ride adjusts the firmness of the dampers to the

current driving situation within a fraction of a second. It also gives

the driver a choice of basic setting for either a more comfortable or a

sportier drive.

Drivers can choose between a comfortable and a sporty driving mode

to suit the driving situation and their personal tastes. In both modes

the suspension’s damping forces are continuously adjusted to the

current driving situation to produce uncompromising road behavior. The

benefits are clearly appreciable both in terms of comfort and handling

characteristics. In the normal mode – when the oil is more viscous and

the degree of damping less pronounced – the car rolls surprisingly

smoothly; this is ideal for long-distance driving or uneven road

surfaces. In the Sport mode, by contrast – when the oil is less viscous –

it reveals an extremely dynamic character that is manifested by a

resolutely firm

grip of the road surface. Rolling movements are suppressed from the very moment the

steering

is turned even more effectively than in the basic suspension setting,

and the steering response is further improved. The self-steering

behavior is further optimized by the specific stabilization provided

for each individual wheel, resulting in a driving feel reminiscent of a

go-kart.

Magneto-rheological fluids and its close relative

electro-rheological - ER - fluid have been around since I think the mid

1940s. I remember first reading about it in the early 80s. It has a

complex name but it involves a concept that's quite simple to

understand.

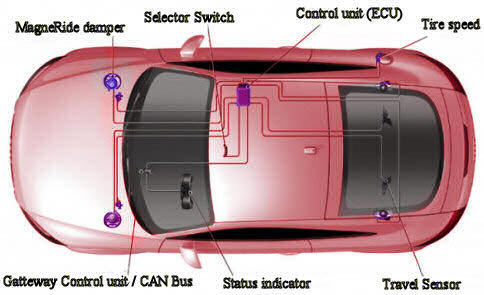

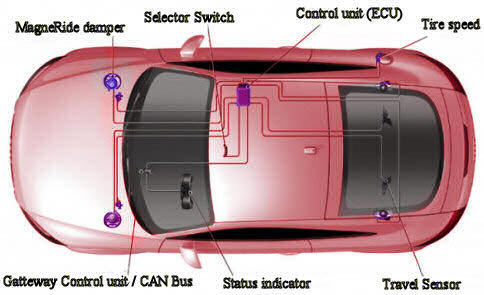

A control unit computes the optimum damping force for the

individual driving situation. It does so using information from the

wheel travel sensors and communication with other systems such as the

steering and ESP.

Since no mechanical parts must be moved, the MR damper responds

extremely spontaneously. The damping force is only dependent on the

power applied to the magneto-rheological fluid and can be adjusted up

to 1,000 times a second. Thanks to the variable control of the power,

the damping force can also be set infinitely. This means the

magneto-rheological dampers respond almost in real time with great

sensitivity to impulses from the road. The control system loop with

Skyhook algorithms ensures the greatest possible road-to-wheel contact

in the case of uneven road surfaces with the least impulses to the car

body. This means the car with Magnetic Ride has the greatest possible

driving dynamics and allows for comfort.

Delphi’s magneto-rheological monotube damper requires roughly the

same space requirements as conventional dampers or struts. If required,

Delphi supplies the complete semi-active system with dampers and

struts including the sensors and the control unit.

Rheology is a science that studies the deformation and flow of

materials. Rheological fluids have flow characteristics that can be

changed in a controllable way using electrical current or a magnetic

field. Depending on the base fluid and the strength of the electrical

current or magnet, the fluid's viscosity can be varied from

thinner-than-water to almost-solid and any stage in between. The

fluid's response is instantaneous, completely reversible and extremely

controllable, but there are some limits.

Electro-rheological (ER) fluid changes viscosity when an electric

current is applied directly to the fluid itself. ER fluid was first

invented and patented in the 1940s, and to varying degrees, development

has continued ever since. It has been tested in a wide range of

applications, from torque converters,

clutches

and dampers to synthetic muscles and dampers in powered prosthetic

arms and legs. It works, but its shear strength (its resistance to

shearing movement) is limited. Despite huge investments in research and

development, ER fluid is still far from ready for any practical

applications.

Magneto-rheological (MR) fluid on other side has shear strength

about 10 times stronger than ER fluid. Invented at the same time as ER

fluid, the two have many similarities. Both can use oil, silicone, water

or glycol as the base fluid, and both contain polarizable particles

suspended in the fluid. Polarizable means the particles can be forced

to align in a specific way. These suspended polarizable particles are

the basic difference between ER and MR fluids. ER fluid uses particles

that polarize when directly exposed to an electric current. MR fluid

uses somewhat larger particles of iron that polarize when surrounded by

a magnetic field.

The typical MR fluid particles are soft iron spheres or

ellipsoids measuring 3 to 5 microns (3 to 5 thousandths of a

millimeter) in diameter. Depending on the application, the fluid will be

20 to 40 percent saturated with the iron particles, and other

additives will be used to control particle settling and mixing, fluid

friction and fluid viscosity. Nanoparticles are covered with protective

polymerous macromolecular coating, so-called surfactant (surface

active agent), that prevents a direct contact between nanoparticles and

causes repulsive forces between them. Specific gravity is generally

between 3 and 4; for reference, water's specific gravity is 1. Thus, a

200 liter drum of MR fluid can weigh almost a full ton. MR fluids are

developed specifically for the application intended. For instance, in

addition to automotive uses, MR fluids have been developed for use in

dampers that protect buildings and other structures from earthquake

damage. These dampers sit still for long periods, so different

additives are needed to keep the particles in suspension.

MR fluid can be used for three different functions: shear mode, squeeze mode and valve mode.

If a very thin layer of MR fluid (eg 0.15 - 0.3 millimeters) is

placed between two electro-magnetic plates - and then the plates are

slid relative to one another - the MR fluid is said to be operating in

'shear mode'. Such method can be used for the production of clutches

and brakes.

A similar set-up - but this time with the plates being pushed

towards one another - is termed 'squeeze mode'. This approach can be

used for damping very small movements.

But of most interest to us is

'valve mode'. This is where

there is a flow of MR fluid from one reservoir to another, with the

connection being through a small diameter passage. If the passage is

subjected to a variable intensity magnetic field, the amount of fluid

that is able to flow will be altered. In effect, the fluid will act as

if the opening changes in size. This approach is used in MR fluid

damper design.

The strength of the bonds between the magnetized iron particles

causes the viscosity of the fluid to apparently increase. The

magnetized fluid is not, technically, more viscous, but it is more

resistant to passage through the restrictions in the damper because the

concentration of magnetized fluid forms a kind of deformable plug.

When a magnetic field is applied to a coil – by means of a pulse

delivered by a control unit, the micron-sized particles dispersed

inside oil used in car dampers (basic synthetic hydrocarbon oil,

polymer liquid, mineral oil or silicone-based fluid), align themselves

along the magnetic lines of force and magnetic particles are aligned

against the direction of movement of the damper. Just like the iron

filings that the science teacher used to shows lines of force around a

bar magnet, the iron particles within the fluid form a pattern. In each

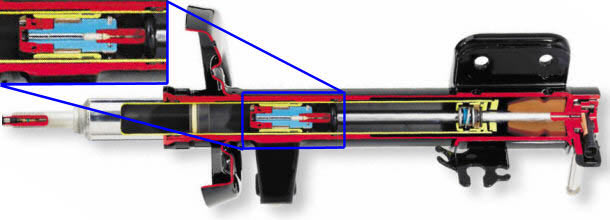

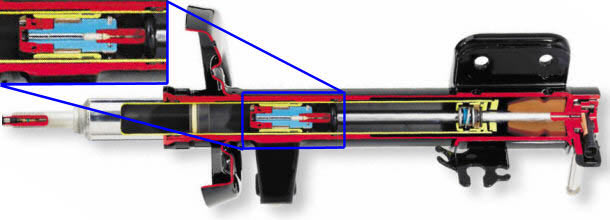

of the monotube dampers are a piston containing two electromagnetic

coils and two or more small fluid passages through the piston. The

electromagnetic coil is integrated into the damper piston in such a way

that when it is energized the magnetic flux runs exactly transversely

to the admission ports in the damper piston. The electromagnets are

able to create a variable magnetic field across the fluid passages and

field can be altered in strength to adjust the damping force in just

100 nanoseconds. When the magnets are off, and the piston moves inside

damper body, the fluid travels through the passages freely.

However, when the magnets are turned on, the iron particles in the fluid create a fibrous structure (

so called magnetoviscous effect)

through the passages in the same direction of the magnetic field. If

the piston moves, the particles aligned in strings like pearls on a

necklace, create flow resistance in the flowing suspension fluid. If,

in order to flow, the 'necklaces' need to be broken, the fluid acts as

if its viscosity has increased. In fact the carrier fluid - let's call

it just oil for simplicity - hasn't increased in viscosity at all, but

the combination of the iron and the oil behaves in a more viscous

manner. This allows the firmness of the dampers to be increased or

decreased within a fraction of a second or gradually. Altering the

strength of the current results in an instantaneous change in force of

the piston. If the sensors sense any body roll, they communicate the

information to the

ECU.

The ECU will compensate for this by changing the strength of the

current to the appropriate dampers. This alters the characteristic of

the damping much faster than is the case in conventional adaptive

dampers and provides the right degree of damping force at each

individual wheel in every situation.

The greater the energy applied and the stronger the magnetic

field, stronger the “necklace“the greater the resistance and damping

power. The energy is controlled in relation to driving dynamics and

impulses from the road. This means for every road situation optimal

damping power is available. This damping power produces – according to

OEM desire – a more comfortable feel or sportier vehicle handling. In

theory, the viscosity of the damper liquid can be changed to an almost

solid state similar to plastic or rubber in composition. As the

viscosity of the liquid changes, it offers a difference in the damping.

Magnetic suspension is described as the fastest reacting

suspension in the world as sensors monitor the road surface up to 1000

times per second and an ECU can make variations within a millisecond

resulting in the possibility of multiple damping variations being made

in a fraction of a second.

Each of the four dampers is adjusted individually and

independently even when it seems that all of them are doing the same

thing. This ensures a comfortable ride along various road surfaces.

Magnetic suspension reduces vibrations, bouncing, noise and body roll

very effectively on all road surfaces and at any speed that the vehicle

could travel. The reduction of body roll may reduce the need for

anti roll bars.

Although this type of suspension offers a very comfortable ride, sport

settings can be applied or tuned into the system to cater for

performance vehicles. Low energy requirements of the system are another

benefit. On average, a damper requires just 5 watts of electrical

power (25 watts at a maximum).

Magnetic dampers are designed with similar dimensions and

connection points to other types of dampers so they are usually

attached to the chassis of the vehicle similar to how a coil spring

suspension would.

The MagneRide controller itself is a stand-alone unit equipped

with two parallel processors: one for input signals and one for output.

It operates the shocks on 5 volts DC that is pulse-width modulated to

adjust current to the magnets. Current draw can spike momentarily at

about 5 amps per shock, but normal current draw is about half that much,

and there is always some current flowing whenever the key is on.

A magnetorheological car damper is controlled by algorithms

specifically designed for the purpose. There are plenty of

alternatives, such as

Skyhook or

Groundhook

algorithms. The idea of the algorithms is to control the viscosity of

the magnetorheological fluid with electric current in the best possible

way. The control module uses

suspension height data supplied by position sensors at each corner. With throttle position sensor (TPS),

transmission and

wheel

speed data supplied by the Powertrain Control Module (PCM), the

suspension controller can predict lift and dive at each end of the car

and operate the shocks' "valves" to counteract it. With data from a

steering wheel position sensor, a two-plane acceleration sensor and a

yaw

rate sensor, the shocks can be operated as needed to control body roll

during any maneuver. The system also checks body movement during

antilock brake system (ABS) operation using vehicle speed, wheel speed

and other data supplied by the ABS control unit. All in all, control

module are constantly checking yaw, pitch, roll and heave of the car

and continuously adjusting dampers.

Like earlier versions, this is a semi-active suspension system.

In addition to its main function of keeping the wheels in contact with

the road, it can check body motions and, within certain limits, adjust

weight bias at each corner by preventing suspension compression. But it

is a reactive system, not proactive, and it cannot extend the

suspension to make the car lean into a turn. Still, it provides a

significant amount of increased control with base settings that are

tuned for a more comfortable ride.

You will likely not see this in the Aftermarket any time soon, though there are people working on it.

At this moment the cost is too prohibitive. Not only is the fluid

expensive, but damper computer control system must be completely

integrated with the car and car’s ECU. Hardware is not a problem, it's

the software that makes all the cool stuff happen, but is also what

takes the longest to develop at the greatest cost. Because of all that

modern car system integration it’s very hard to implement aftermarket

magnetic damper system and interface it to existing car system.

For

the moment, you can find some systems for use in competition on

aftermarket. One example of these systems is “SDS” (Selective Damping

System) MagneShocks™ for Oval-Track and Road-Race. System can allow you

to adjust your suspension on your liking without changing dampers

itself during

set-up.

You actually have a hundreds of different dampers (settings) in one

damper set. But dampers are not adaptable like in fully integrated

systems on before described road going cars. You can select from 50

different Pre-Programmed rebound Force-Velocity Curves and from 50 more

compression curves (2,500 different possible curves) to exactly tune

for every conceivable track condition. One is selected, that’s it.

There is no further adaptability to road condition. The MagneShock is

composed of 4 components: controller box, 4 dampers, programmer box and

selector switch in the cockpit for “in-race” manual adjustments.

You can make some of this exotic stuff at home. Just mix some

powdered iron filings with a thick liquid like corn oil, and presto: a

simple MR fluid. Hold a magnet nearby and the bits of iron will line up

end-to-end; they form a rigid lattice that stiffens the mixture. Take

the magnet away and the fluid will relax again.

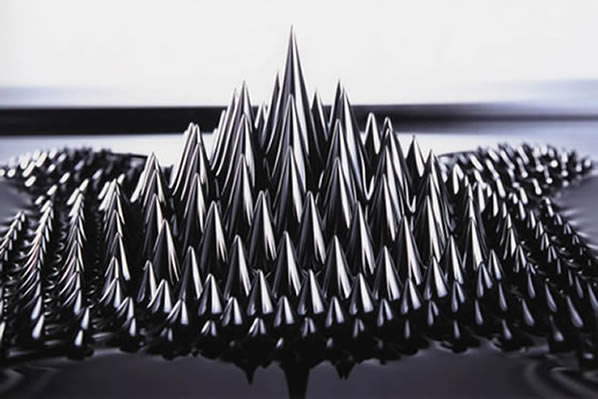

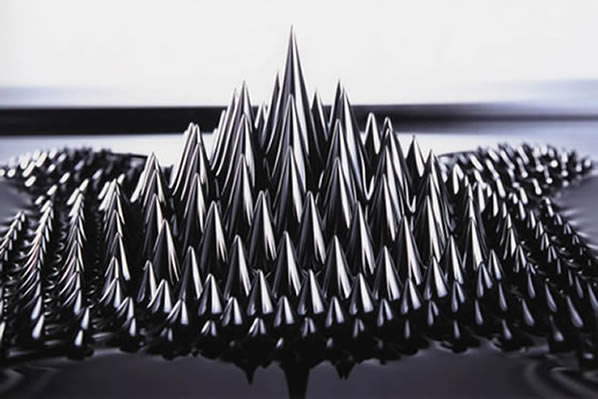

Put bit of a MR fluid on the plate and magnet under it and things

get strange. The interaction of the magnetic field, the surface

tension of the ferrofluid and gravity results in the formation of stable

spikes of liquid. The spikes are still liquid - touch one and you'll

just get an oily finger - but if you don't move the magnet, they look

like a solid sculpture.

The stronger the field, the smaller the spikes. In the weedy

field from a ferrite magnet you'll get just a smooth mound of fluid

with a few spikes where the field is strongest, but the spikes get a

lot smaller when you're playing with one of the bigger neodymium

magnets.

With reference to

http://www.formula1-dictionary.net/damper_magnetorheological.html

of Historic Places in order to protect it against salvagers.

of Historic Places in order to protect it against salvagers. of Historic Places in order to protect it against salvagers.

of Historic Places in order to protect it against salvagers.

These systems were produced by the Delphi Corporation and now by

These systems were produced by the Delphi Corporation and now by

MR fluid can be used for three different functions: shear mode, squeeze mode and valve mode.

MR fluid can be used for three different functions: shear mode, squeeze mode and valve mode.

For

the moment, you can find some systems for use in competition on

aftermarket. One example of these systems is “SDS” (Selective Damping

System) MagneShocks™ for Oval-Track and Road-Race. System can allow you

to adjust your suspension on your liking without changing dampers

itself during

For

the moment, you can find some systems for use in competition on

aftermarket. One example of these systems is “SDS” (Selective Damping

System) MagneShocks™ for Oval-Track and Road-Race. System can allow you

to adjust your suspension on your liking without changing dampers

itself during